Imagine your inventory is no longer a high-cost game, but a competitive strength?

Profits to most companies are leaking into their inventory. Too much stock ties up cash. A mismanaged inventory redirects customers to other competitors.

An examination of the global supply chain invariably shows that 20% to 30% of the inventory of business organisations is either surplus or outdated, or slow-moving, and with no audible margin or cash flow (Tech Crunch).

The traditional in-house inventory control is failing to adapt to the developments in quicker, volatile, and information-driven markets. The nighttime demand is increasingly changing, supply problems have become the norm, and customers nearly insist on near-perfect supply.

In-house management of this complexity is typically related to higher payroll costs, ineffective systems, and reactive decision-making . This is the reason why inventory management outsourcing is no longer simply a cost-saving strategy, but a change driver.

Today, outsourcing inventory companies are gaining access to specialized knowledge, forecasting predictive systems, and scalability without paying the additional costs of building their own.

According to industry standards, the companies that exploit the outsourced inventory and logistics operations perform admirably in reducing their carrying costs by 10-25 percent, and simultaneously, the performance in the order fulfillment and inventory turn is also improved.

Outsourcing is one of the means by which businesses can exit the world of guesswork for accuracy . Instead of recovering after stockouts or overstocks when it is too late, the benefits of proactive control are enjoyed by the businesses to optimize inventory, gain better visibility of the supply chain, and release working capital to invest once again in growth.

In the tightening margin business environment where speed is now more than ever before, it is not really a matter of whether or not to outsource inventory management, but when you can do without it.

What is Logistics Outsourcing?

Outsourcing of logistics entails engaging external people to handle your supply chain. They take care of transporting to warehousing and inventory handling (Speedy Freight). They provide efficiency in delivery, inventory, and optimum stock.

Transportation

Experts in logistics deal with transporting goods, which are delivered fast and efficiently. By road, sea, or air, they are familiar with the most economical methods of reducing costs and shortening delivery times.

Warehousing

Warehousing does not deal with product storage. Logistics partners ensure the protection of your stocks and protect them with the help of technology.

Inventory Management

Fine inventory management refers to the amount of stock that one has at the right time. Logistics providers can track inventory and predict demand to ensure that you get what you want.

- Inventory Management: Focuses on the available products.

- Supply Chain Management: An overview of the entire process of acquiring products from the suppliers to the consumers.

It is crucial to know both of them, more so as your business expands.

The benefits of outsourcing and global manufacturing include reducing expenses, reducing consumer prices, and generating employment. – Larry Elder (Brainy Quote).

Harvard claims that Hewlett-Packard (HP) was unable to make profits off its PCs in the 1990s, even though it was acquiring a customer base (Oxford Academic). The company, true to its margin, had a thin margin on some of its products, some of which have not been making money since 1993.

This was because of the declining prices and high rate of product cycles. As PCs were depreciating at the rate of 1 per cent per week, it became important to keep a check on inventory expenses.

HP found out that the traditional inventory accounted for approximately 10 percent of their total costs. They discovered that greater undercover expenses were associated with the imbalances between demand and supply. These expenses encompassed the component devaluation expenses on parts that were being produced.

They were also taking into account the cost of price protection when the prices fell, when the distributors had old inventory (Oxford Academic). Also, there were costs of product returns of unsold products. Obsolescence expenses were incurred on products that were not sold by the retailers before new models came into existence.

HP enhanced the management of its supply chain by effectively monitoring such expenses. This strategy gave product groups the chance to select optimal strategies to suit them. Rather than implementing a blanket inventory reduction, how HP did it is a lesson to other companies.

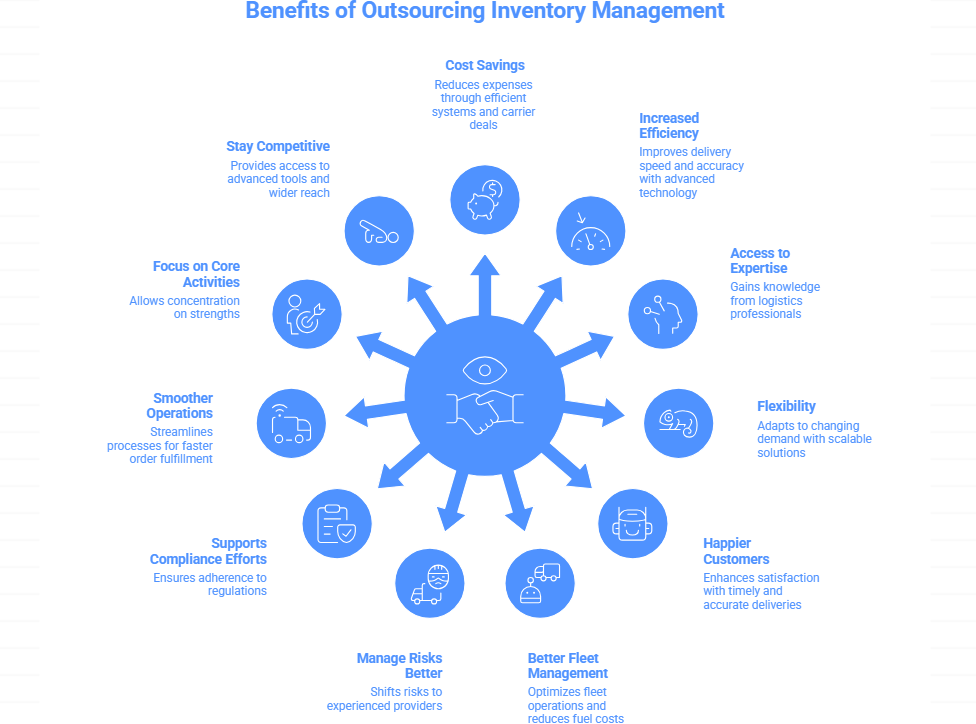

Top 12 Inventory Management Outsourcing Benefits

1.Cost Savings

Outsourcing saves money by using the provider’s systems and networks. They often have deals with carriers, lowering shipping costs, and you save on warehousing and labor expenses.

2.Increased Efficiency

Logistics experts use optimized processes and advanced technology to improve the speed and accuracy of deliveries. This means fewer mistakes and faster service (TOV Logistics).

3.Access to Expertise

When you outsource, you gain access to the knowledge and experience of logistics professionals. They stay up to date on the latest trends and can help you improve your operations. For example, experts at Expertise Accelerated enhance your business’s agility and responsiveness to market changes.

4.Flexibility

Outsourcing allows you to adjust to changes in demand. Providers can adjust to your needs, whether scaling up for busy seasons or down during slow periods.

5.Save Money

Outsourcing logistics saves businesses money in several ways. It reduces payroll costs by using logistics experts, cutting the need for extra salaries. Companies avoid costs for buying and maintaining trucks or vans and investing in warehouses or storage. This approach allows businesses to cut costs while focusing on their core operations.

6.Happier Customers

Outsourcing logistics speeds up delivery and boosts customer satisfaction. Logistics companies offer quicker shipping options, helping ensure products arrive on time. They also reduce mistakes, so customers receive the right orders. Plus, customers can track their shipments, which adds to their satisfaction. Outsourcing logistics improves customer service and builds loyalty.

7.Better Fleet Management

Outsourcing logistics can help your fleet work better. It helps you save money by using resources and cutting fuel costs. Logistics companies also use advanced tools to manage fleets and ensure timely deliveries. Expert managers improve logistics decisions, helping your business grow.

8.Manage Risks Better

Outsourcing logistics helps businesses reduce risks. By working with experienced providers, you can shift many shipping and storage risks to them. They can help you follow industry rules, so you stay compliant (ShipBob). Logistics experts also prepare you for unexpected problems and create plans to handle them. Plus, they can improve how you manage your inventory. This way, you can focus on growing your business while keeping risks low.

9.Supports Compliance Efforts

Outsourcing logistics helps businesses keep up with regulations in several ways. First, logistics providers, or 3PLs, offer expert guidance by understanding the rules and ensuring you follow them. This reduces risks by lowering the chance of compliance issues.

Additionally, outsourcing can cut compliance-related costs. By partnering with logistics experts, you can stay compliant while focusing on your main business.

10.Smoother Operations

Outsourcing logistics also makes operations run more smoothly. One major benefit is faster order fulfillment, as logistics partners ensure quick processing of orders. They also provide better inventory management by keeping track of stock levels.

Moreover, outsourcing can lead to cost reduction by saving on transportation and storage expenses. These improvements enhance performance for businesses.

11.Helps Focus on What You Do Best

By outsourcing logistics, you can concentrate on your strengths. Letting professionals handle logistics boosts efficiency, allowing you to focus on core activities. This also enables better resource allocation, allowing you to spend more time and money where it matters most. This strategy promotes growth while experts manage logistics.

12.Stay Competitive

Outsourcing logistics gives your business a competitive edge. You gain access to the latest tools, as 3PL providers use advanced systems to enhance service quality. Additionally, they offer a wider reach, ensuring efficient service across various locations. Outsourcing helps you focus on product development and stay competitive.

Real World Examples of Efficient Inventory Management

Marygrove Awnings keeps extra stock on hand to avoid ordering frequently and ensure supplies are always on hand (NetStock).

This strategy saves money by buying in bulk for discounts and reducing shipping costs by filling their trucks. However, this approach might not work for everyone, as you need to consider the costs of storage space (and whether the savings are worth it).

You may also need to hire someone to manage the extra inventory. As your business grows, using inventory management software can help keep everything organized.

7 Steps to an Effective Inventory Management System:

Good inventory management does not need complicated systems or huge budgets. The only thing it needs is organization, uniformity, and transparency. These 7 steps represent a realistic base, which is effective in both small and growing businesses.

1.Establish the nature of entry and flow of inventory in your business.

Begin with a clear understanding of the process of purchasing, receiving, storing, and selling products (PackageX). Either you purchase your suppliers locally or import in large quantities, knowing lead times, minimum order quantities, and triggers to restocking will eliminate overbuying and shortages. Inventory issues do not necessarily start when the inventory is stored, but when buying it.

2.Single system to track inventory.

Do not handle stock in two or more notebooks, two or more email accounts, or disconnected tools. Visibility can be generated by one spreadsheet or an entry-level system such as Square POS or QuickBooks Inventory. That is all that counts: all the sales, returns, and purchases should be under a single record to ensure accuracy.

3.Standardize product identification.

Each product must have a distinct, identifiable number or a SKU, or a barcode. This saves time, confusion, and human error is minimized during picking and selling, and increases with the size of your product range. Reporting, re-ordering, and audits are also much easier with clear product codes.

4.Plan physical storage.

The inventory must not be stored without a purpose. Store the products in the same place and make the shelves or bins very identifiable. Employees can figure out where things go and, therefore, the fulfillment process becomes fast, and the number of misplaces decreases. One of the quickest methods to enhance the efficiency of operations is a well-arranged system of storage.

5.Maintenance: Use sales history to plan future stocking.

You have one of the best forecasting tools in past sales data. The analysis of seasonal trends, fast-moving, and slow-moving products can help you know the demand better. This helps in minimizing the dead stock, enhances cash flow, and makes the most popular products available whenever customers come in need of them.

6.Check the received inventory on the spot.

Always verify received inventory with the purchase orders. Record quantities, check quality, and record discrepancies immediately (PackageX). Early detection of errors at delivery will avoid downstream problems like stock inaccuracies, billing problems, or dissatisfaction with the services received by a customer in the future.

7.Conduct frequent counts of inventory.

No system remains correct without verification. Periodically have counts of cycles or regular full inventory counts so that it can balance records with actual stock. These audits reveal shrinkage or recording errors or gaps in the process, before it becomes a loss of money.

Why This Matters?

Managing inventory is not about having a great idea of what is in your shelves; it is about safeguarding cash flows, enhancing service providers, and making certain business decisions. With visible and controlled inventory, the business can move faster, use less waste, and develop more predictably.

Conclusion:

There is no such thing as neutral inventory decisions. Excessive inventories are cash-consuming and add holding costs. Lack of supply will cause lost sales, dissatisfied clients, and fire drills in operations. The winning businesses are not those that guess better, but the ones that put in place the inventory methodically, with data, and the appropriate knowledge.

This is where the outsourcing of inventory management will be a strategic move as opposed to a cost decision.

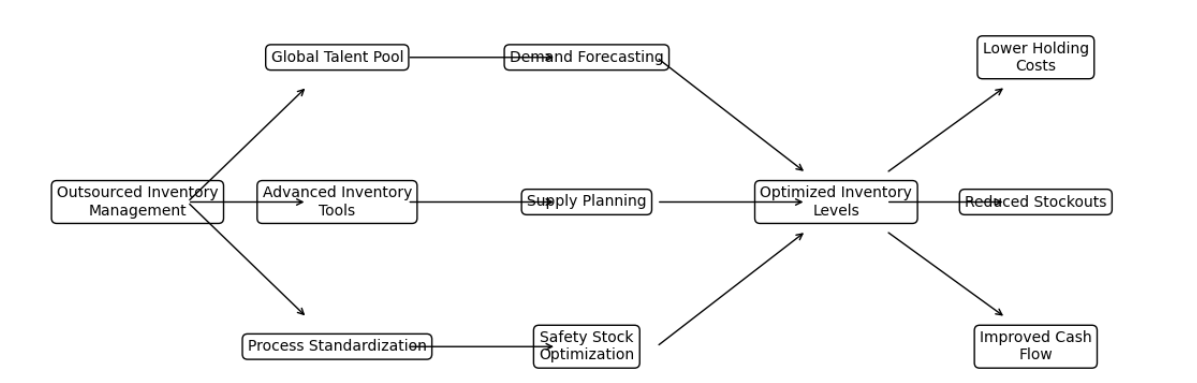

In Expertise Accelerated, there is no longer a need to have inventory management using spreadsheets and reactive decisions. Our inventory outsourced partners assist companies to maintain the right level of inventory, minimize stocks and backorders, eliminate stockouts, and enhance the level of cash flow predictability. All decisions are based on data demand patterns, supply constraints, safety stock reasoning, and working capital influence.

Using the talent pool of EA worldwide, you acquire highly-trained inventory and supply chain professionals who are on par with the U.S.-based professionals, but at a fraction of the expense. This will enable you to scale with smartness, adapt quickly to market changes, and reinforce your supply chain without necessarily having to hire, train, or keep your own teams.

Reasons why Businesses prefer EA in Inventory management:

- Reduced operating expense, without reducing expertise.

- Increased cash flow by decreasing inventory on hand.

- Reduced stockouts and improved service level.

- Support that expands as your business does.

- Operating 24/7 and with regular implementation.

- Best practices that have been tested by the industry in the retail, manufacturing, e-commerce, CPG, restaurants, and real estate sectors.

By outsourcing inventory to EA, you have the capacity to pass on to your internal teams the aspects of growing, strategising, and customers, whilst the complexity of the task is left to be undertaken by the seasoned professionals.

Expertise Accelerated is poised to assist you if you are ready to quit locking up cash in inventory unpredictability and begin to operate leaner, smarter operations.

Get a one-hour free call NOW, get control of your inventory back!