Imagine that your greatest cash drain is not in marketing, hiring, or even bad sales, but inventory that is lying on the shelves. Recent research on supply chains indicated that 20-30 percent of the working capital of businesses remains tied up in excess or slow-moving inventory (Arda Cards). Stockouts cause the retailers to incur costs estimated to be about 1.1 trillion annually around the world (IHL Group).

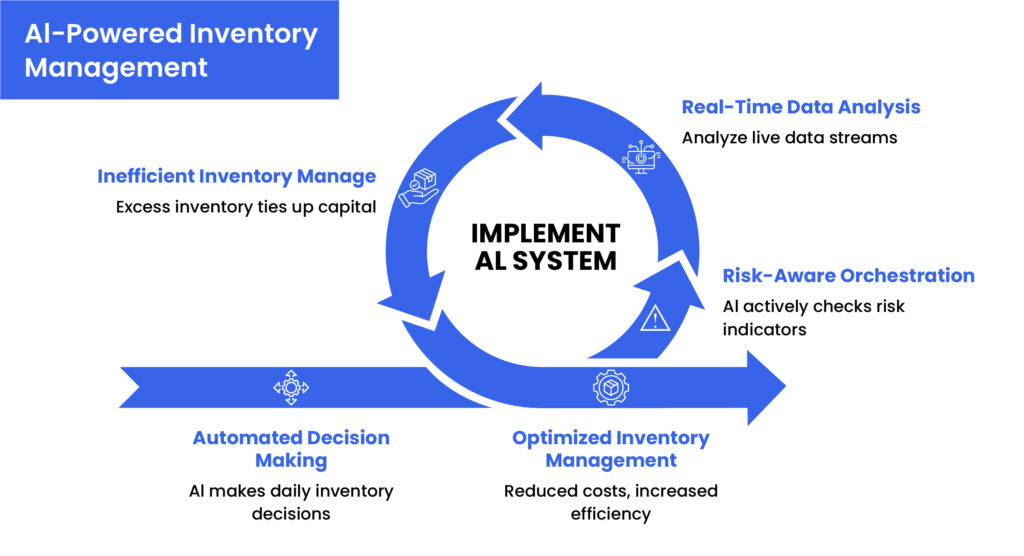

Meanwhile, the current demand trends are changing with greater speed than conventional planning cycles can accommodate. This is where AI comes into the picture as not as an add-on in the future, but as a decision engine that is practical and sees demand shape prior to human intervention.

Assigns inventory dynamically in real time and transforms inventory into a competitive edge. The question is no longer, can AI reduce inventory management, but what costs businesses to continue with inventory management as it was being done in the past?

The Transition to Optimization and Autonomy:

Over the years, AI in inventory management has been a supporting system flagging low inventory (Forbes), recommending the reorder quantity, or generating forecasts that remain to be interpreted and acted upon by a human.

That has been transformed essentially. Nowadays, most major retailers and manufacturers do not rely on AI to give advice to planners, but to make daily inventory decisions. In the grocery chains internationally, e.g., AI is currently used to predict demand, order replenishment, and redistribute stock across stores once it has been automated (Klover). And human teams only intervene when something does not behave as it should.

This change does not mean that people should be taken out of the process, but the delay should be done away with. The days of reviewing inventory decisions have been reduced to a matter of minutes, and this enables businesses to react faster to demand than to the pace of the internal approval process.

Key Takeaways:

- AI is no longer a decision support tool but a decision-making tool in fundamental inventory processes.

- Predicting, replenishing, and assigning tasks is now automated and at scale.

- Human supervision is becoming more exception-driven rather than process-driven.

Why it matters:

Automated inventory controls minimize friction, reduce the response time, and eliminate minor delays to expensive stockageries or unsold inventory. Companies that continue to use manual approval in making daily inventory choices are not only slower, but they are structurally less competitive.

Real-Time Demand and Supply Intelligence:

The conventional inventory planning process was based on fixed data snapshots, such as the sales of the last month, annual trends, or seasonality (Thomasnet). That strategy fails in a world where demand may change overnight, and supply discontinuities may present without any notice.

This is addressed by modern AI inventory by analyzing live data streams across the business and even further. An example of this is in the retail fashion where AI systems today can now detect sudden shifts in purchasing behavior at both the store and online levels. It can instantly divert an inventory towards high-demand areas, usually before the planners realize the trend.

This real-time intelligence transforms inventory from a reactive operation to a predictive operation. Businesses make corrections before demand is even formed and shelves are empty, or warehouses are overstocked.

Key Takeaways:

- Using inventory AI, live internal and external data is used instead of reported data.

- The changes in demand and supply risks are recognized before they influence the availability.

- The inventory decisions are constantly readjusted.

Why it matters:

Demand and supply volatility can be avoided instead of being absorbed by the businesses through real-time demand and supply intelligence. Where speed and availability directly affect the revenues and customer trust. Inventory foresight has become a strategic edge, not a luxury.

Inventory That Controls Finances:

Inventory was considered an operational issue, which supply chain teams handled and which was reviewed by finance on a periodic basis (Deloitte). That division is no longer so. In the current times, CFOs use AI-based inventory systems to affect cash flow and working capital directly.

In manufacturing and retail groups, AI has become a determinant of the extent of capital investments in inventory, inventory turnover, and the location of waste inventory, slowly consuming margins. Inventory AI outputs are already being used to direct financing decisions and cut borrowing requirements by some enterprises, and stabilize cash position during unpredictable demand cycles.

Through real-time linkage of stock decisions and financial results. AI transforms inventory management into a balance-sheet tool and not a back-office activity.

Key Takeaways:

- The direct effects of inventory AI are on the cash flow and working capital efficiency.

- Slow and overstocking of an item is detected and rectified sooner.

- The financial teams can have real-time visibility of the risk of inventory.

Why it matters:

Cash is held up when there is mismanagement of inventory. AI allows companies to unlock that frozen capital without compromising access, allowing the leadership to be more flexible in how they finance the growth, how they deal with debt, or how they handle uncertainty.

Risk-Aware Inventory Orchestration:

In contemporary supply chains, efficiency is insufficient. The actual issue that is encountered by businesses today is dealing with volatility – be it the unstable suppliers, transportation delays, or a boom or bust in demand. It is now handled by AI-based inventory systems that actively check risk indicators throughout the supply chain.

Artificial intelligence in manufacturing sectors such as electronics and automobile production can identify potential issues in product delivery or shortages of other components (Science Direct). AI can automatically reroute inventory orders before problems trickle down into production failures.

Instead of responding when something goes wrong. AI coordinates the movement of inventory to minimize exposure and limit risk as it arises.

Key Takeaways:

- Risk detection, as opposed to optimization, is now part of inventory AI.

- The risks in terms of supplier, demand, and logistics are taken care of in advance.

- Inventory decisions are dynamic in reaction to the changing risk conditions.

Why it matters:

Uncontrolled inventory risk does not remain in a single location, but the operations, finances, and customer trust are spread all over. Businesses can accept the shocks without being disrupted through risk-aware orchestration, which transforms inventory into a force and a stabilizer.

When Full AI Adoption Makes Sense:

Whether AI is capable of inventory management is no longer the question before businesses in 2025, but rather whether the organization is designed to allow it to do so (McKinsey & Company). Complete adoption of AI does not describe a situation in which people have been thrown out of the loop; instead, the role has been redefined.

In large-volume retail and global production, and intricate logistics systems, firms that have adopted AI-led execution enable systems to make routine decisions on a large scale, and the leadership is occupied with strategy, governance, and exception management.

The outcome is not the automation, but the execution with more speed and consistency with human judgment applied where it is really needed.

The difference between productive and reluctant adopters is not the readiness of the technology itself, but the readiness of the organization, which is evident in the presence of the rules of the process of clear escalation, the level of confidence in the quality of the data, and the coordination between operations and finances.

Key Takeaways:

- Complete AI implementation is most effective with large volumes, complicated inventory systems.

- Human beings change to be operators and strategic overseers, as well as decision arbiters.

- Proper governance makes the difference between AI boosting and degrading results.

Why it matters:

Decision speed and consistency have become the drivers of the competitive gap in managing inventory. Companies that are not ready to leave AI to do its job run a risk of being outrun not due to their tool’s weakness, but because of their slower processes. It is the ability to discern when to leave AI to have its way and when to intervene that makes inventory intelligence a continued benefit in 2025.

10 Tips For Artificial Intelligence Inventory Management in SMEs:

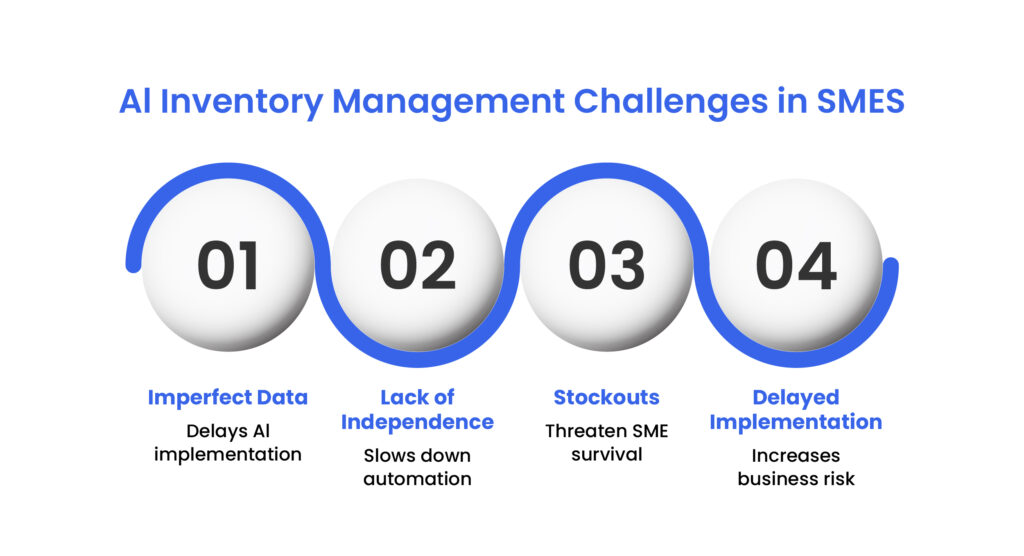

AI Reduces Cash Lock-In Before it Reduces Costs.

In the case of SMEs, the greatest victory is not efficiency, but instead the release of cash that is bound in overstocking to allow it to grow, payroll, or market (Harvard Business Review).

You Do Not Have To Have Perfect Data To Begin.

The combination of sales patterns, seasonality, and other external indicators makes modern AI tools possible even with small historical data, thus it can be used even with a growing business.

Automation Removes Micromanagement of the Owners.

The AI manages a regular rearrangement and stock management to ensure that the business owners do not have to make inventory decisions manually every week.

Stockouts Kill SMEs.

This is in contrast to the large corporations, where the loss of customer trust is quicker in case the product is unavailable, but with AI, it is possible to predict the demand in advance, thus avoiding the situation where shelves are empty.

AI Keeps Up with Inventory Decisions Better Than Humans.

The replenishment and allocation decisions take minutes to execute with AI, and this ensures that SMEs do not lose sales due to delays that usually occur during sudden demand peaks.

AI Makes Inventory a Cash-Flow Decoder.

With the matching inventory to the actual sales velocity, the SMEs will be capable of stabilizing monthly cash flow rather than speculating the future requirements.

Matters of Risk Detection Are Better Than Forecast Accuracy.

In the case of SMEs, timely information regarding delays of suppliers or decreased demand is more important than a flawless forecast, which alerts to the problems even before they arise.

You Do Not Need Complete Independence on Day One.

SMEs can begin with AI-based suggestions and proceed to full automation of execution as trust and quality of data are enhanced.

Human Supervision is Strategic and No Longer Operational.

Owners and managers are concerned with prices, expansion, and supplier bargaining as opposed to checking stock counts.

Waiting Too Long: The Actual Risk.

The reason why SMEs lag in adopting AI is not that they fail to produce a superior product, but because their competitors can refill their stores sooner, use less waste, and react quickly.

Bottom Line for SMEs

Inventory management AI is no longer a luxury for an enterprise, but it is a survival and scalability instrument. To the small and mid-sized business, automation is not an end in itself, but rather a way to control cash, speed, and individual risk in an ever more unpredictable market.

Why Expertise Accelerated Is The Smarter Way to Operationalize AI Inventory Management:

The use of AI-based inventory management gives results only when the strategy, implementation, and financial discipline operate in harmony- and herein lies the difference between Expertise Accelerated and its competitors.

Instead of providing standalone software or a generic automation, EA integrates AI-informed inventory intelligence with expert inventory services, which makes the decision-making process not only fast but also cost-effective and operationally viable.

Expertise Accelerated is a business ally that assists companies in keeping the right inventory levels to reduce unwanted stock, avoid stockouts, and enhance the cash flow with the help of data-driven planning.

Introducing AI knowledge into the daily routine of inventory operations, EA makes sure that the inventory decisions are constantly improved according to the demand trends, real-life situations with suppliers, and financial goal achievement. It is a method that enables firms to realize the stuck working capital, enhance order accuracy, and grow without introducing unwanted complexity into the firm.

What really distinguishes EA is its outsourced inventory management model, which provides businesses with a global talent pool of highly trained inventory expertise-professionally on par with the US counterparts and at a fraction of the cost. Enterprises can have 24/7 support, scalability that is built in, and industry experience in retail, consumer packaged goods, manufacturing, e-commerce, restaurants, and real estate without the hassle of recruitment, training, and payroll tax.

Rather than making an option between in-house control and outsourced efficiency, EA will provide both: AI-based inventory synchronization with human judgment where it is most needed. The outcome is an accelerated decision-making process, improved control over cash and inventory that promotes, as opposed to inhibits, growth.

Recap: Inventory Intelligence Is Not an Option:

The management of inventory has taken a new dimension. What was previously a back-office functional activity has become a core source of cash flow, strength, and competitive edge. AI has transformed inventory planning. But to is executed dynamically as it anticipates demand, limits risk, and frees capital in real time. In both cases, to the enterprise, as well as the SME, the old way of inventory management is no longer inefficient, but it is a lost opportunity.

The victors in 2025 and further on will not be the ones with the highest data and the largest systems, but the ones that can respond to intelligence faster and more consistently than their rivals. When combined with the right combination of AI-informed knowledge and proven inventory specialists, organizations will be able to transform volatility into control and complexity into clarity.

Expertise Accelerated makes such a transition feasible, scalable, and financially feasible. Inventory intelligence is not only holding stock anymore in the contemporary marketplace, but a growth-sustaining process.

Request a free appointment with the expert panel of EA and get started on inventory that is not hostile to your business.