We can order products worldwide with a few clicks, but how does it happen?

For businesses, the answer is the global supply chain. It links materials, factories, and shipping to deliver products.

But what happens if things go wrong like accounting challenges in the supply chain?

Supply chain problems happen when goods are late. A hurricane postponed a ship from India to the U.S., resulting in casualties. In 2025, inflation, high interest rates, and supply chain problems and climate change harmed businesses. An APQC survey shows 84% of firms changed their supply chain strategies. Changing demands and globalization make supply chains difficult.

Key Takeaways

- Supply chains connect raw materials to customers worldwide.

- Events like COVID-19, Brexit, and the Ukraine war show they can break easily.

- Inflation, worker shortages, and higher fuel costs are big challenges now.

- Accounting helps control costs, reduce risks, and follow rules.

Things to Consider

- Don’t depend on one supplier.

- Keep enough stock to avoid shortages but not too much to waste money.

Use tech to see stock in real time. - Train teams on global compliance rules.

Note

Supply chain challenges are not always avoidable, but planning reduces the impact.

Bonus Point

Companies that invest in AI forecasting and digital tools bounce back faster during disruptions.

Disclaimer

This blog provides general insights into supply chain and accounting challenges. It is not financial or legal advice. Businesses should consult qualified experts for specific guidance.

Chart

| Challenge | Example | Impact | Solution |

| Material shortages | Chip shortage in cars | Delays, high costs | Use more suppliers |

| Fuel costs | Shipping price hikes | Costly transport | Optimize routes, track. |

| Forecasting demand | Heat waves→cold drinks | Stockouts, overstock | Use data and AI |

| Labor shortages | UK driver gaps | Delivery delays | Hire local, automate |

| Tariffs and rules | Brexit checks | Border delays, cost | Train staff, go digital. |

How Supply Chains Work

A supply chain moves a product from raw materials to the customer. Each step depends on the next, so problems raise costs. A strong supply chain lowers costs; a weak one raises them.

Demand Forecasting Firms need to predict how much of a product customers will want. If they underestimate demand, items sell out too fast, leading to lost sales. If they overestimate, products pile up in warehouses. For example, Supermarkets use past sales and weather to plan. In heatwaves, they stock more drinks and ice cream.

Sourcing Materials: Reliable suppliers are vital. Apple uses many suppliers for iPhone parts to prevent disruptions. Ford and GM had to stop production in 2021 due to microchip shortages.

Logistics and Transport Moving materials to factories and products to customers is key. High fuel costs and customs checks can delay deliveries, like Marks & Spencer after Brexit.

Types of Supply Chain Models

- Efficiency-focused models

The continuous flow model works best when customer demand is steady and predictable. For example, bakeries use this model to produce fresh bread every day since people buy it. The efficient chain model uses JIT, delivering materials only when needed. Toyota is a well-known example of this system. It reduces storage costs but also brings risks. Toyota ran into problems in the 2011 Japan tsunami and recent chip shortages because parts didn’t arrive on time. The fast chain model suits industries with quickly changing demand, like fashion. Zara is a prime example, moves clothing from design to store shelves in only weeks to keep up with fast fashion - Responsive models

The flexible model suits seasonal demand, like Costco stocking up before holidays to meet higher sales. The agile model handles unpredictable demand, as Amazon did during COVID-19. It expanded warehouses and delivery services to handle the sudden surge in online shopping. The custom-configured model lets customers choose features, as with BMW and Tesla cars. They let buyers choose car features and designs before manufacturing them.

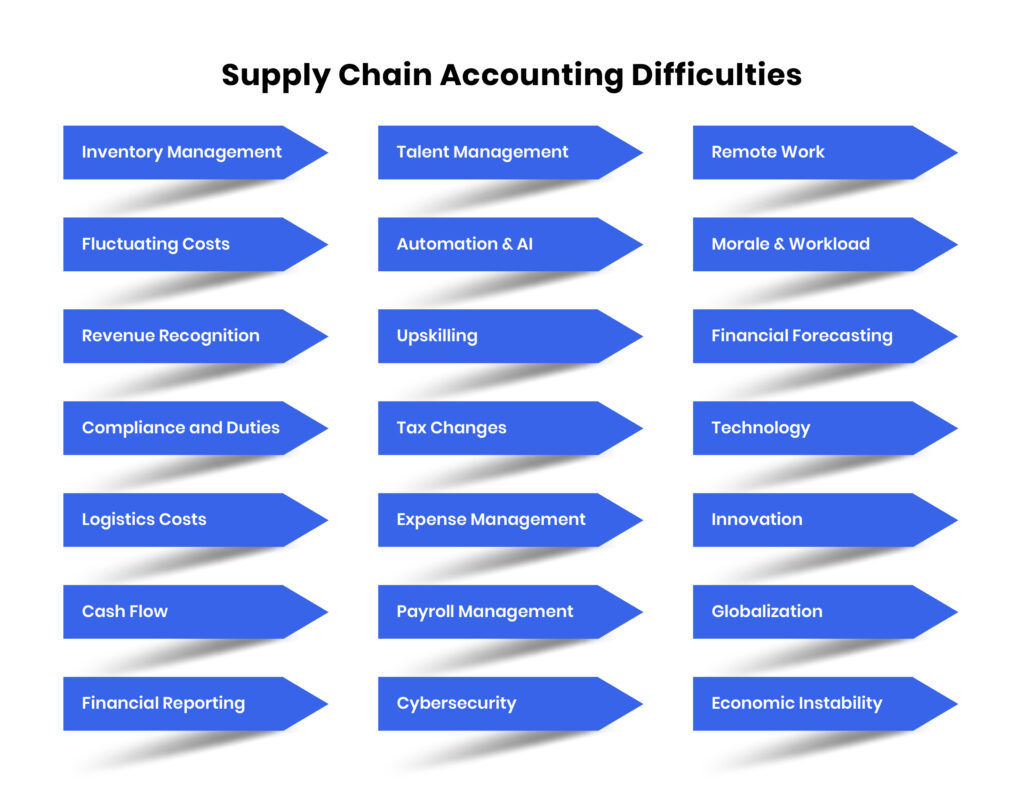

Supply Chain Accounting Difficulties

Today’s supply chains face shortages, high fuel costs, and changing demand. Companies must focus on real sustainability, not “greenwashing.” Labor shortages since the pandemic make hiring and keeping staff harder.

Several factors are reshaping supply chains. Technology like AI, automation, and blockchain speeds up business and online demand. Stricter rules, transport limits, COVID-19, Panama Canal, and climate events like floods and storms make supply chains harder to manage.

There are a list of modern day accounting challenges that supply chain face, but there are some of the common accounting challenges in supply chains:

- Inventory Management – Calculating inventory cost is tricky. Methods like FIFO, LIFO, or average cost affect profit and taxes. Large stocks risk damage or obsolescence. Example: Fashion retailers using FIFO may show higher profits during inflation.

- Fluctuating Costs – Prices shift due to markets, politics, or supply. Example: Auto makers face steel hikes or chip shortages. Currency changes add extra costs.

- Revenue Recognition – Timing of orders, delivery, and payment can confuse revenue recording. Example: Goods shipped in January, paid in March. Clear policies prevent errors.

- Compliance and Duties – Different countries have taxes and tariffs. Example: U.S. imports to the EU face VAT and rules. Software and local experts help avoid penalties.

- Logistics Costs – Fuel, routes, and warehouse fees affect expenses. Example: FedEx passes on fuel hikes. Track costs and optimize routes.

- Cash Flow – Materials and shipping tie up money. Example: Retailers importing bulk goods wait months to sell. Automate invoices and manage payments.

- Financial Reporting – Global rules change often. Example: Warehouses under new accounting rules. Automate reporting and train staff.

- Talent Management – Businesses need skilled accountants. Example: Logistics firms in Asia face shortages. Offer training and mentorship.

- Automation & AI – Automate tasks like invoice tracking. Example: UPS uses AI for route optimization. Start small, then scale.

- Upskilling – Accountants need ERP and analytics skills. Example: SAP/Oracle skills help plan purchases. Cross-train for teamwork.

- Tax Changes – Tariffs and taxes shift frequently. Example: U.S.–China tariffs affect pricing. Use compliance tools and update records.

- Expense Management – Shipping and supplier fees can spike. Example: Retailers pay higher freight in peak season. Use dashboards and policies.

- Payroll Management – Rules differ globally. Example: Amazon follows many regions’ payroll laws. Cloud systems help automate.

- Cybersecurity – Supply chains share sensitive data. Example: Maersk ransomware caused losses. Audit, train staff, enforce security.

- Remote Work – Managing global accounting is harder remotely. Example: Closing books slows without centralized systems. Use cloud platforms.

- Morale & Workload – Heavy workload can burn out staff. Example: Customs paperwork overwhelms accountants. Automate tasks and reward achievements.

- Financial Forecasting – Predicting risks is key. Example: During COVID-19, good forecasting helped companies adapt. Run scenario models.

- Technology – Old systems fail to handle global supply chains. Example: Spreadsheet-based firms struggle. Invest in ERP and AI.

- Innovation – Automation frees accountants for strategy. Example: AI scans customs forms for errors. Combine AI insights with human checks.

- Globalization – Managing currencies and compliance is crucial. Example: Apple coordinates suppliers worldwide. Standardize reporting, adapt locally.

- Economic Instability – Inflation or currency shifts affect costs. Example: FMCG packaging costs rose sharply. Cloud ERP helps adapt, and maintain cash reserves.

Brexit caused a shortage of 100,000 truck drivers in the UK, making McDonald’s run out of milkshakes in 2021. COVID-19 and transport issues delayed goods. Like Samsung and Apple, delayed launches and supermarkets limit essentials. While the Ukraine war raised costs, caused Volkswagen to face shortages, and increased food prices.

Building Supply Chain Resilience

- Use many suppliers – Apple sources chips from both TSMC and Samsung to reduce risk.

- Work with local suppliers – UK breweries buy local barley to avoid customs delays.

- Keep safety stock – Tesco stockpiles food and household items before Christmas.

- Learn customs – DHL trains staff to handle paperwork and avoid delays

- Use digital tools – Amazon uses AI to predict demand and improve supply chains

- Balance stock – Keep enough items to meet demand, not too much

- Use data – Predict demand with analytics, not only past trends

- Cut returns – Set clear rules, stay transparent, and use customer reviews

- Increase visibility – Track products in real time with AI and supply chain software.

Conclusion

Supply chains are the backbone of every business, and accounting challenges in supply chains make them tougher. One part failing slows everything, raising costs and upsetting customers. Toyota, Amazon, and Tesco show that many suppliers, safety stock, and digital tools ensure resilience. Flexibility costs more initially but prevents costly disruptions later. Businesses can’t control the economy but can manage finances.

Expertise Accelerated CPAs help businesses control costs, stay compliant, and keep finances accurate. We work with clients across industries to make supply chain accounting easier and more efficient. EA organizes data, automates tasks, and saves time to cut costs and stay compliant. Contact us today to book a call.

Faqs

- What drives supply chain setbacks?

Slowdowns happen because of bad weather, disasters, politics, pandemics, or wars. For example, hurricanes can restrict shipments, Brexit slowed customs, and COVID-19 paused factories. High fuel costs, fewer workers, and transport limits also cause delays. Firms use thorough planning and technology to check shipments and prevent issues.

- How do supply chain issues affect businesses?

Interruptions increase expenses, cause lost sales, and upset clients. Production and stock can be interrupted, and growing energy or material costs lower profits. Unexpected demand makes planning harder, and firms may struggle to follow regulations and ethical norms. Flexible plans, security stock, and digital tools permit lessening the effect.

- How are companies responding to supply chain challenges?

Businesses expand vendors, keep excess stock, and use digital tools to check and expect demand. Automation, AI, and analytics aid in controlling delays. For instance, Amazon raised its storehouses during COVID-19 to cater to increased demand. Firms also review supply chains to rectify vulnerable areas and prepare for disturbances.

- What role does technology play in supply chains?

Technology makes supply chains faster, accurate, and easier to manage. AI, automation, and blockchain track shipments, handle inventory, and forecast demand. Tools cut mistakes and save time. Cloud systems allow teams to work together globally. Using technology well enables firms to reduce expenses, deliver quickly, and address disturbances.

- How do global events like the Ukraine war affect supply chains?

Global events can raise costs and cause shortages. The Ukraine war increased energy and transport costs and caused wiring shortages for cars. It has even increased global food prices since Ukraine ships much of the world’s grain. Firms must search for alternative suppliers and adapt quickly. Flexible and strong supply chains enable handling these shocks.