Managing inventory is about keeping the right balance. If you manage it well, your business runs smoothly, you save money, and your customers stay happy. But if you don’t, you might end up with too much stock that doesn’t sell or run out of products when customers want them.

Inventory management is keeping the right stock without overfilling. It helps you avoid extra costs, work more efficiently, and keep customers satisfied.

A report by PR Newswire found that US retailers have only 63% inventory accuracy, causing frequent stock issues.

In this blog, we’ll share simple inventory tips to keep your business ahead.

What is Inventory Management?

Inventory management means making sure you always have the right amount of products, not too much and not too little. If you have too much stock, it wastes space and ties up your money. If you have too little, you miss out on sales and upset customers. But inventory management isn’t about counting boxes. It means using methods like JIT to order only when needed, ABC Analysis for key items, and Safety Stock for emergencies. Inventory software helps track stock in real-time and keeps you organized.

Good inventory software updates your stock on all selling platforms like your website, Amazon, and eBay. It shows live stock levels, so you don’t run out or overstock. It can also predict what you’ll sell and help you adjust before problems happen. You can manage everything from your phone or tablet. It also automates tasks like stock updates and order tracking, so you work less and make fewer mistakes.

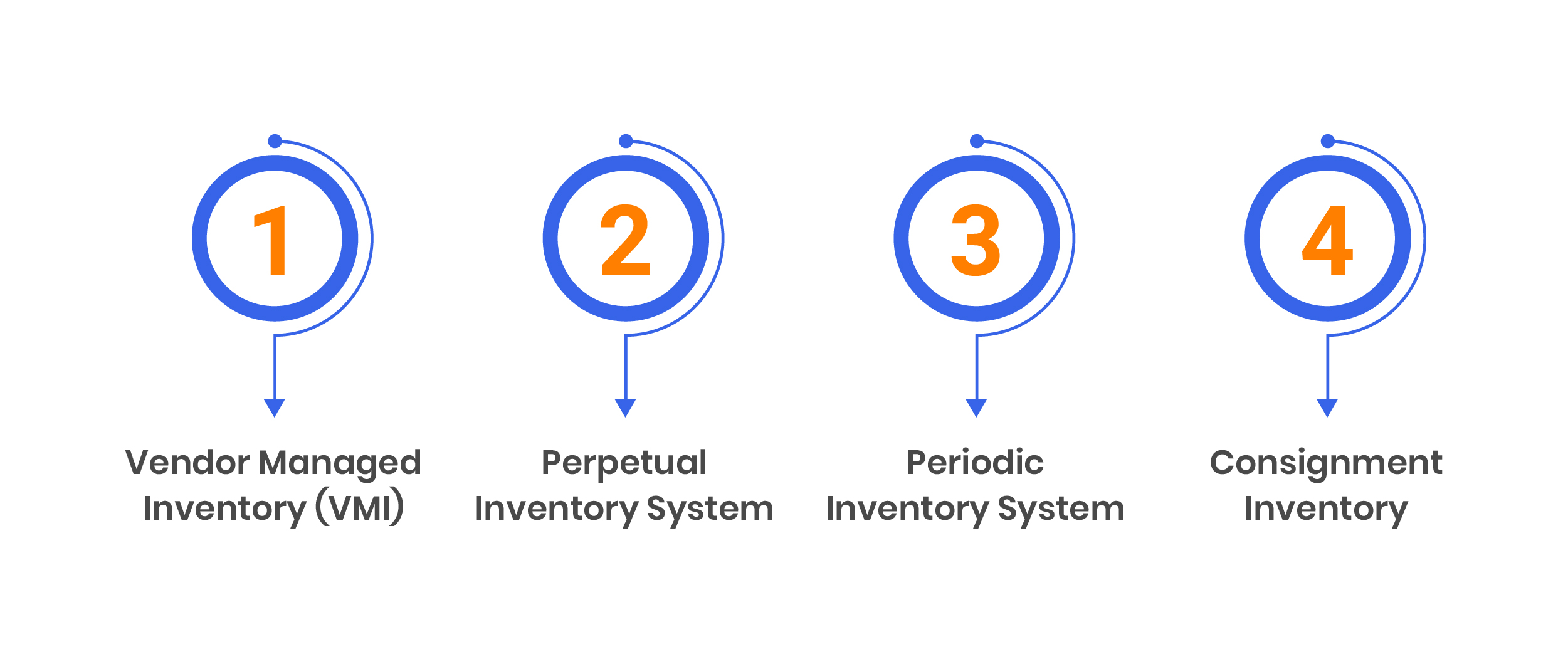

Types of Inventory Management Systems

1. Perpetual Inventory System This system tracks inventory in real-time using software and technology. Pros: Gives live updates and better accuracy. Cons: Requires advanced tech and costs more.

2. Periodic Inventory System Check inventory every month or each quarter. Pros: Simple and low cost. Cons: Stockouts or overstocking can happen between checks.

3. Vendor-Managed Inventory (VMI) Supplier monitors stock and restocks when needed. Pros: Reduces buyer’s work. Cons: Needs good data sharing and trust with suppliers.

4. Consignment Inventory The supplier owns the stock until it’s sold. Pros: Buyer saves on holding costs. Cons: The supplier holds the risk until they sell the products.

Benefits of Good Inventory Management

- Keep the right amount of stock.

- Cuts storage and holding costs.

- Frees up cash for other business needs.

- Speeds up business operations.

- Helps better decisions with accurate data.

Inventory Management Methods

1. Demand Forecasting predicts demand by studying past sales and trends. MOQ is the minimum units a supplier will sell, while EOQ is the ideal order size to reduce costs. If MOQ exceeds EOQ, you risk overstocking and higher storage costs. Below MOQ risks extra fees. Negotiate, bundle orders, or reschedule to prevent overstocking. Knowing MOQ and EOQ helps you plan and save. For example, Walmart uses data to manage stock and cut costs. Benefits: fewer stockouts, lower costs, and smarter planning.

2. ABC Analysis Sort products into three groups.

A: High-value items that need tight control.

B: Medium-value items.

C: Low-value items aid businesses to focus on profitable products.

3. Just-in-Time (JIT) Inventory Order only when needed to cut storage costs. Example: Car makers use JIT to avoid extra parts. Benefits: Less waste, more efficiency, quick response to demand changes.

4. Safety Stock and Batch Tracking: Safety stock is extra inventory kept as a backup for sudden demand or supply delays. For example, electronics stores keep extra stock of popular items to avoid stockouts. Batch and serial tracking means tracking products with unique numbers. It’s useful in industries like pharmaceuticals for easy recalls and better inventory control. Both methods keep businesses ready and manage inventory well.

5. Economic Order Quantity (EOQ) helps businesses order the right amount to cut inventory costs. MOQ is the smallest quantity a supplier will sell. If MOQ is higher than EOQ, you risk overbuying and wasting space. Ordering less than MOQ may lead to extra charges. To balance, you can negotiate MOQs, combine orders, or align EOQ with sales forecasts. Review past sales, peak seasons, and storage space to adjust orders. This saves money and keeps inventory in control. Benefits: Lowers costs, avoids overstocking, and enriches stock management.

6. Return-Merchandise Authorization A system to manage product returns. Benefits: Improves service, tracks return reasons, and eases returns.

7. Cycle Counting Cycle counting is an easy way to keep track of your inventory without stopping your business. Instead of doing a big, full stock check, you count small sections of your inventory regularly. This catches mistakes early and keeps stock records accurate without stopping business. It’s very helpful for online stores with many products or warehouses.

You don’t need to count every item the same way. Check expensive or fast-selling items often to avoid costly mistakes. Count slow-selling or cheaper items less often. This saves you time but still keeps things accurate. Modern inventory systems make this even easier. They remind you to count, update stock in real time, and reduce order mistakes.

Cycle counting prevents stockouts and overstocking. It also shows you if certain suppliers or products are causing repeated errors. Over time, this makes your inventory management much better. Use automated systems for cycle counts to save time, keep inventory accurate, and catch problems early.

Inventory Management Best Practices

- Use ERP software to manage inventory better.

- Forecast demand accurately using sales data.

- Apply lean inventory methods like JIT.

- Keep safety stock for emergency needs.

- Work closely with suppliers for better coordination.

Choose software that syncs stock across all sales channels. Real-time tracking helps you always know what’s in stock to avoid running out or overstocking. Good software also predicts what products you’ll need based on past sales. Mobile access manages inventory anywhere. Automation saves time and cuts errors.

Measuring Inventory Management Success

To manage inventory well, there are a few important things to track. The Inventory Turnover Ratio shows how you sell and replace products. Stockouts and Overstocks tell you how often you run out of items or have too much stock. The Order Accuracy Rate checks if customer orders are being fulfilled correctly. Lead Time and Replenishment Time measure how fast you can restock products. Carrying Costs keep track of storage and handling expenses. Sales Forecast Accuracy checks your sales forecast.

Conclusion

Good inventory management saves cash, boosts efficiency, and keeps clients happy. It’s easier than you think. FIFO, LIFO, JIT, ABC, cycle counting, and order management reduce waste, save costs, and keep you organized. It’s not about tracking products, it’s about making smart decisions that help your business grow. With the right tools, you can prevent stock issues, please customers, and boost profits.

At EA, we help businesses improve their inventory management. Our solutions help you save money, work faster, and grow your business. Partner with us to level up