Whether it’s a small business or a big company, tracking inventory is vital. If you don’t manage your stock properly, you could lose a lot of money. In fact, businesses lost over a trillion dollars in 2014 because of inventory mistakes.

Most inventory mistakes happen because of small problems in daily processes. Repeated small mistakes may point to a bigger management problem. That’s why it’s important to not fix the mistake but also find out why it keeps happening.

Today, businesses want to save money but still give good service to customers. One smart way to do this is by outsourcing inventory and logistics. This means hiring experts to handle your stock, storage, and shipping. These experts use advanced tools to help your business grow while keeping costs low.

Meteor Space says that fixing stock shortages and having too much extra stock can save a business up to 12%.

Outsourcing inventory helps reduce mistakes and saves you time. When experts manage your stock, you can focus on growing your business while saving money.

What is Logistics Outsourcing?

Logistics outsourcing is hiring experts to handle transport, storage, and stock management. They ensure products arrive on time and stock stays accurate.

Inventory Management means tracking stock to avoid running out or overstocking. Supply Chain Management handles the entire process from suppliers to customer delivery. Both are very important because they help your business run smoothly and grow.

According to Forbes, Keep improving inventory management as business and technology change. The smart way is to create a system that keeps learning and getting better. Be ready to fix your mistakes and others’. Small problems will happen. What matters is how you handle them. Always find ways to work smarter and help your team. Inventory management needs constant improvement to avoid problems, stay competitive, and grow your business.

Keith Oliver introduced “supply chain” in 1978 to manage product flow efficiently. Now, with COVID-19 disruptions, he warns that moving manufacturing back home will raise costs. The real problem is not the supply chain but poor management and underused tools. Risks like strikes and pandemics are often overlooked. Businesses should plan “what-if” scenarios and have backups. Don’t rely only on technology, supply chains need smart human oversight. Despite current challenges, Oliver remains optimistic. This crisis could push companies to finally give supply chains the strategic importance they deserve.

Example

HP (Hewlett-Packard) once had problems with too much stock and falling prices. They realized that simple inventory costs were not the only problem. Hidden costs like old unsold stock, product returns, and price drops were hurting profits. By fixing how they tracked these problems, HP improved its supply chain and saved money.

Marygrove Awnings keeps extra stock to avoid frequent re-ordering. This helps them buy in bulk for discounts and saves on shipping. But, they need extra space and someone to manage it. As businesses grow, using inventory management software helps keep track of everything.

Benefits of Outsourcing Inventory Management

1. Save Money – Lower costs on shipping, storage, and staff.

2. Work Faster – Experts help you deliver quicker with fewer mistakes.

3. Expert Advice – Get help from people who know logistics best.

4. Be Flexible – Adjust quickly for busy or slow seasons.

5. Lower Expenses – Cut costs on transport, storage, and staff.

6. Happy Customers – Faster and more accurate deliveries.

7. Better Fleet Use – Efficient use of vehicles and lower fuel costs.

8. Manage Risks – Outsource risks like damages and delivery problems.

9. Stay Legal – Experts help you follow rules and regulations.

10. Smooth Operations – Faster order processing and inventory updates.

11. Focus on Business – You can focus on sales and growth.

12. Stay Competitive – Use the latest tools and reach more customers.

Challenges In Outsourcing Inventory Management

1. Not Having a Proper Product Catalog

One of the biggest inventory mistakes is not keeping a complete product list. Every business needs a product catalog of all items new, incoming, and discontinued. Use Excel or software with product name, code, status, prices, stock, supplier, and forecasts. It is important to keep this catalog updated. You can’t make it once and forget about it. A good product catalog is the foundation of solid inventory management. It helps track stock and avoid shortages or overstocking.

2. Not Tracking Key Performance Indicators (KPIs)

To manage inventory better, track key numbers called KPIs. Important KPIs include product availability, stock life, forecast accuracy, and timely delivery. Focus on 2 to 4 KPIs that matter most to your business for clear improvement.

3. Focusing Only on the Sale Price

Buying cheap isn’t always best. Total cost of ownership (TCO) includes order size, defects, supplier reliability, delivery time, and product lifespan. Paying more for a better supplier can save you from costly problems later.

4. Too Many Storage Locations

Storing products in many places makes inventory management harder and causes mistakes. Keep stock in one main place and use many sites only for slow deliveries, unpredictable sales, or large, costly items. Centralizing stock reduces errors.

5. Poor Forecasting for New Products

Ordering new products without planning can lead to overstock or shortages. Check past sales, delivery times, stock needs, and sales risks to avoid mistakes.

6. Having Too Much Warehouse Space

Having too much warehouse space often leads to storing products you don’t need, to fill up the space. It’s better to keep your warehouse about 85% full so you only stock what’s necessary. Also, make sure your warehouse is close to your business. If it’s far away, visit it often to keep an eye on your inventory. If you don’t check, stock problems can go unnoticed and cause bigger issues later.

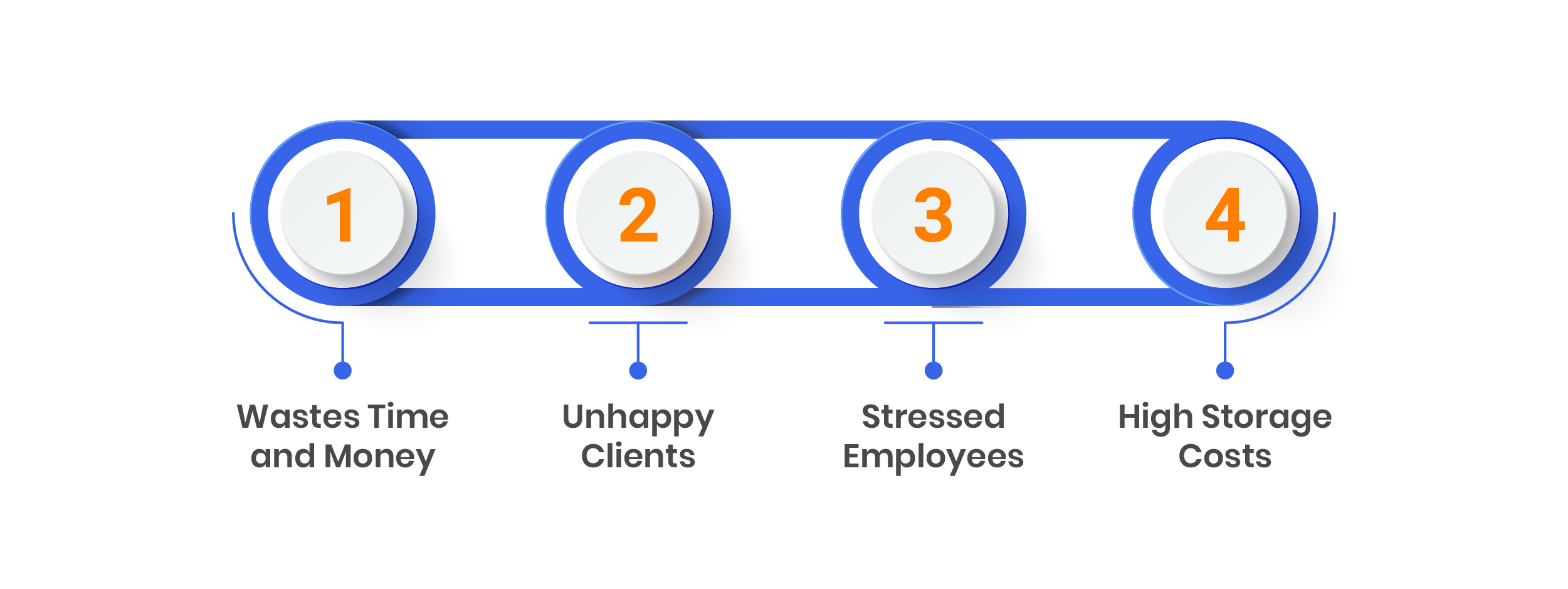

How These Mistakes Can Harm Your Business

Wastes Time and Money: Fixing mistakes wastes resources.

Unhappy Clients: Errors cause delays and wrong orders.

Stressed Employees: Bad systems make work harder for your team.

High Storage Costs: Keeping too much stock increases your expenses.

Inventory Management Outsourcing Best Practices

- Plan how you will buy and store products.

- Use a simple sheet or app to track stock.

- Make clear labels or codes for your products.

- Organize items in labeled places.

- Check past sales to predict future stock needs.

- Always check deliveries that match your orders.

- Count your stock to avoid mistakes.

Conclusion

Inventory management is not a one-time job. You need to check and improve it all the time. Simple things like keeping your product list updated and training your team are very important. If stressed, list problems, ask why they happen, and how to fix them. An expert can spot hidden issues. Fix small issues to prevent big losses, keep customers happy, and increase profits. Outsource logistics and inventory management services to experts to save time and costs. Experts like Expertise Accelerated handle this, so you can focus on growth.